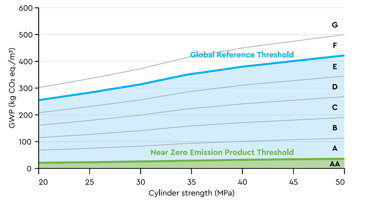

A landmark initiative by GCCA with multigovernmental organisations sets low carbon concrete...

Recarbonation of Concrete: From EPDs to Whole-Life Carbon Accounting

Recarbonation of Concrete: From EPDs to Whole-Life Carbon Accounting

1. Introduction

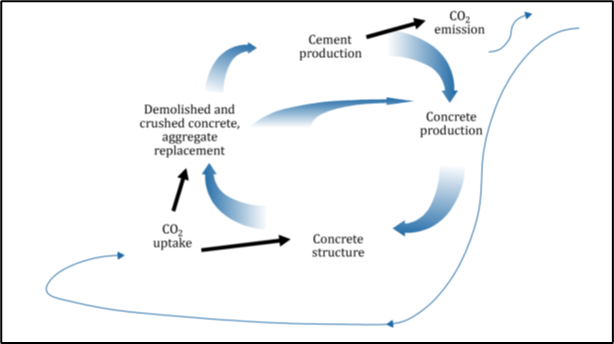

Recarbonation is the natural process by which CO2 in the atmosphere reacts with the calcium oxide in concrete to form calcium carbonate. Recarbonation is a significant CO₂ uptake mechanism that must be reflected in whole-life carbon accounting for concrete products and buildings. This uptake partially "rebinds" CO₂ emitted during clinker and cement production, offsetting gross embodied carbon. Over a concrete product's life cycle, substantial recarbonation can occur during precast storage, throughout the in-service period in buildings and structures, and after demolition when concrete is crushed, stored, recycled, or landfilled.

Today, EN 15804 (core rules for construction product Environmental Product Declarations) and EN 16757 (Product Category Rules specific to concrete and concrete elements) establish a framework for transparent recarbonation accounting at the product level. The GCCA EPD Tool implements these standards, offering material manufacturers three approaches (detailed, default, and user-defined) to estimate CO₂ uptake across lifecycle modules A3 (precast storage), B (use stage), and C3–C4 (end-of-life).

However, this product-level approach has an inherent limitation: material producers typically do not know the actual in-service exposure, surface area, and design life of their concrete in a specific building or asset, so they rely on generic scenarios and conservative defaults. While appropriate for product transparency, this generalisation can significantly underestimate (or, less often, overestimate) the true whole-life recarbonation of concrete in a given project.

This paper provides a recommendation for the next phase of recarbonation accounting: integrating material-producer EPD data with designer and client knowledge of building-specific use conditions through BIM-enabled whole-life carbon tools. We outline how current standards define ("Now”), how the GCCA EPD Tool implements this today, why the product-level approach is limited, and how digital EPDs and BIM modelling can together enable more accurate, project-specific recarbonation calculations (“Next”).

2. Recarbonation and Its Significance

Concrete carbonation occurs as CO₂ from the atmosphere penetrates the concrete and reacts with calcium oxide to form calcium carbonate. This process not only strengthens the concrete but also removes CO₂ from the environment. Concrete products absorb CO₂ during different stages of their lifecycle: during their use as structures and post-demolition when crushed or landfilled. Additionally, precast elements can carbonate during production and storage.

Given the potential for concrete to reabsorb a significant portion of the CO₂ emitted during its production, recarbonation is a vital factor in assessing the true carbon footprint of cement-based products.

Figure 1: CO2 cycle in cement and concrete (Source: EN 16757, Annex BB)

To demonstrate low or net-zero embodied carbon, accurate recarbonation accounting can have a material impact. Recarbonation depends heavily on in-service conditions that only the designer and building owner can specify, therefore, to progress towards more accurate whole life carbon assessment this better understanding of service conditions must be integrated.

3. The Current Standards: EN 15804 and EN 16757 (The NOW)

3.1 EN 15804 and Core LCA Rules

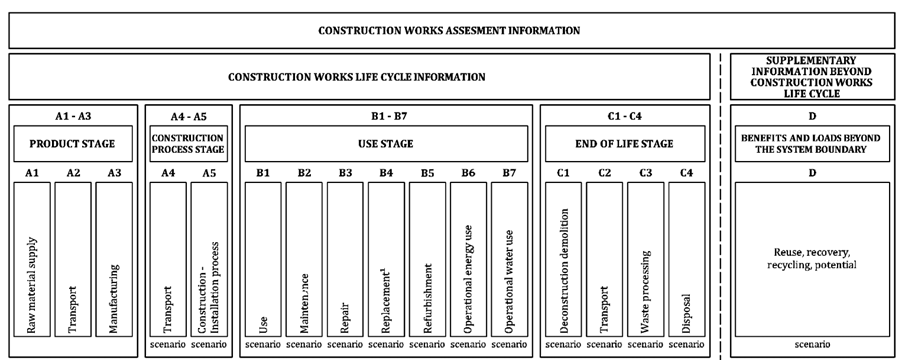

EN 15804 establishes the core rules for Environmental Product Declarations (EPDs) of construction products. It defines the lifecycle stages (A1–A5 for product and construction; B1–B7 for use; C1–C4 for end-of-life; and D for benefits and loads beyond the system boundary) and mandates that EPDs report environmental impact indicators in a standardised format.

EN 15804 also recognises that CO₂ uptake by carbonation and permits (but does not mandate) the inclusion of CO₂ absorption in life-cycle modules, provided that assumptions and methods are transparently documented. The standard requires that when CO₂ uptake is excluded, this must be clearly stated, ensuring that users can identify and adjust for incompleteness if needed.

3.2 EN 16757 and Concrete-Specific Rules

EN 16757 supplements EN 15804 with detailed Product Category Rules (PCR) for concrete and concrete elements. Annex BB of EN 16757 provides comprehensive guidance on calculating CO₂ uptake by carbonation, including a specific method based on carbonation depth, reactive CaO content, cement composition, exposure class, and service life.

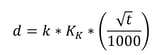

The EN 16757 Annex BB method models recarbonation depth as a function of the square root of time, with a carbonation coefficient (k-factor) that varies by exposure class and concrete strength. The k-factor accounts for the fact that stronger concrete carbonates more slowly, and exposure affects diffusion rates, “exposed to rain" typically gives faster carbonation than "sheltered" or "indoors". The method then converts carbonation depth to CO₂ mass using the reactive CaO fraction, cement content, and binder composition.

EN 16757 also specifies that carbonation should be considered in modules B (use), C3 (waste processing), and C4 (disposal), and optionally in A3 for precast products with significant storage exposure. For each module, the method requires or defaults to specific assumptions on exposure class, service life, and surface area, reflecting the reality that, at product level, these parameters are often unknown.

4. The GCCA EPD Tool: Modelling of recarbonation

4.1 Overview

Recarbonation is treated as an optional element in EN 15804 and EN 16757: producers may omit it, provided they state this clearly. However, both standards strongly encourage its inclusion, and the GCCA has made it standard practice in its EPD Tool.

The GCCA EPD Tool, developed by the Global Cement and Concrete Association, implements the EN 16757 / EN 15804 approach to recarbonation modelling. The tool allocates CO₂ uptake across modules A3 (precast storage), B (use stage), C3 (crushed concrete storage before recycling), and C4 (landfilled or permanently stored concrete).

For each module, the tool models the balance between the material's carbonation potential determined by its binder composition, reactive CaO, and strength, and the exposure conditions determined by environment, time, and accessible surface area. This separation of material and exposure parameters is key to understanding both the current product-level approach and the opportunity for BIM-enabled refinement discussed later in this paper.

Figure 2: Lifecycle stages and modules (Source: EN 15804)

4.2 The EN 16757 Annex BB Calculation Method

The GCCA tool employs the EN 16757 Annex BB formula for CO₂ uptake per unit exposed area (m2):

The term d is the depth of carbonation in mm, defined as:

![]()

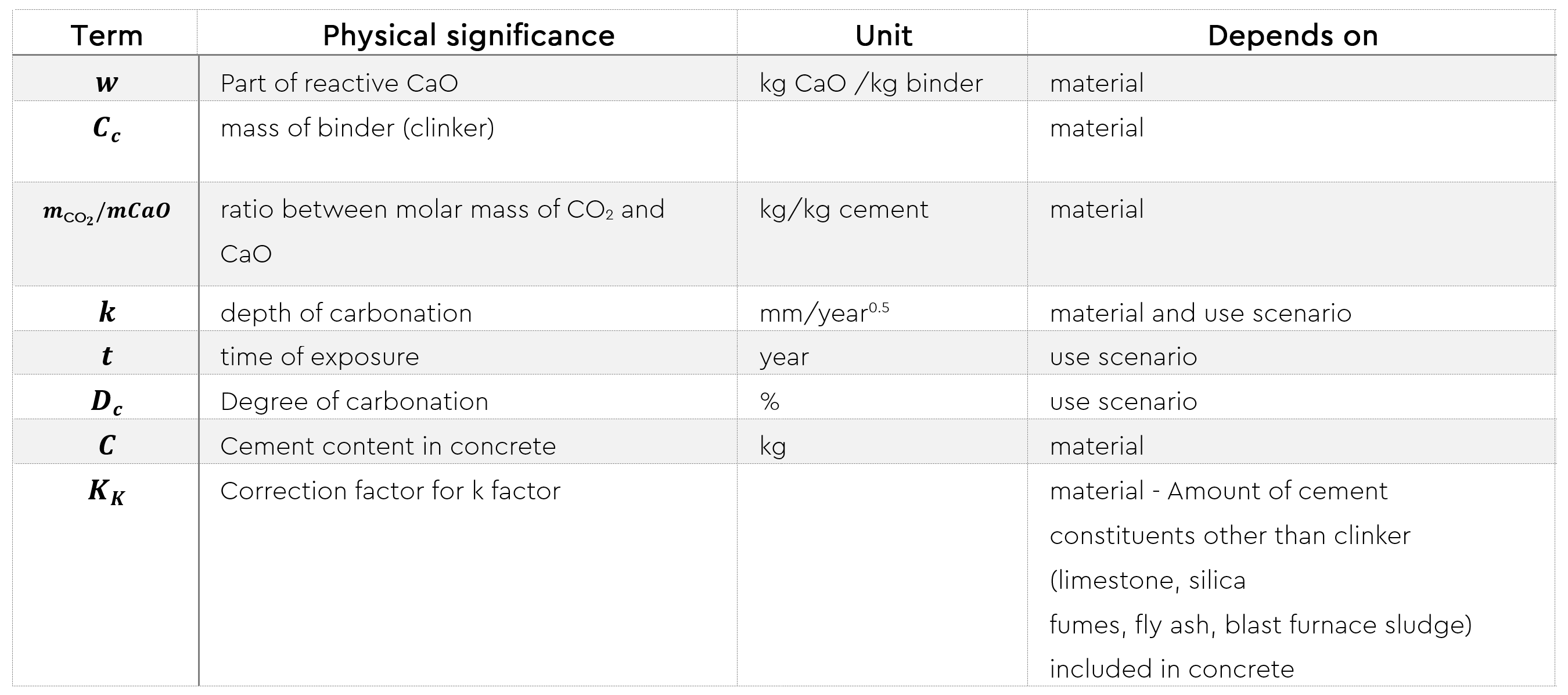

The other terms are defined as follows:

The other terms are defined as follows:

The formula terms depend on either the he material or use scenario, or in the case of “d”, both. Today, the calculation of carbonation for concrete EPDs use specific material parameters but typically rely on generic defaults for the use scenario parameters, because the material producer who is responsible for the EPD generally does not know the use scenario (see section 5.0). An exception is a producer of a precast concrete product (e.g. railway sleeper, concrete pile, floor unit).

4.3 Three Approaches to Recarbonation Calculation

The GCCA EPD Tool offers three calculation methodologies, reflecting different levels of available data and desired accuracy:

- Detailed Approach

The detailed approach for calculating recarbonation across life cycle stages is outlined as follows:

Manufacturing stage (A3) (for precast products): The tool user inputs the storage duration, exposure conditions, and surface area exposed to recarbonation per cubic meter of product.

Use stage (B): The tool user provides the lifespan of the structure and selects exposure conditions for the product.

Waste processing (C3): The tool user inputs the storage duration before reuse and selects exposure conditions.

Waste disposal (C4): No detailed approach is provided; the default approach is used.

For all stages, exposure conditions are requested as input. In accordance with EN 16757, the exposure conditions are: “Exposed to rain”, “Sheltered”, “Indoor in dry climate with cover”, “Indoor in dry climate without cover”, “In ground”, and “Under groundwater level”. If the exposure conditions are selected as “unknown”, the tool considers the option that minimises recarbonation[1].

For Modules A3 and B the tool user must define the surface area exposed (m2/m3) whilst for Module C3 the tool considers spherical particles of 150 mm diameter with radial recarbonation.

- Default Approach

When detailed data are not available or practical to input, the GCCA tool uses conservative default assumptions that reflect typical building and infrastructure exposure scenarios:

Manufacturing stage (A3) (for precast products): No default approach is provided; only the detailed approach is available.

Use stage (B): The tool user selects the type of structure, which determines exposure duration and surface area per volume. If the structure type is unknown, default options are used (see Table).

Waste processing (C3): The tool user inputs the storage duration before crushed concrete is reused and selects the exposure conditions.

Waste disposal (C4): The tool assumes a 100-year exposure for carbonation for landfilled products.

|

Calculation parameter |

Module B |

Module C3 |

Module c4 |

|

Duration of exposure |

- Buildings (default): 50 years[2] - Infrastructure: 100 years |

3 months |

100 years |

|

Exposure conditions |

Most conservative option is selected[3] |

Exposed to rain |

In ground |

|

Exposed surface area |

- Buildings[3]: 6 m2/m3 - Infrastructure (default): 2 m2/m3 |

Spherical particles of 150 mm diameter with radial recarbonation |

|

Table 1: Module-specific parameters for recarbonation, default approach (Note: For Module A3 only the detailed approach applies)

- User-Defined Approach

For modules B, C3, and C4, tool users may input a single CO₂ uptake value per functional unit, derived from their own calculations, external standards, or project-specific studies. This approach offers flexibility for producers with access to region-specific carbonation data or for special product categories (e.g. elements designed for high-exposure applications).

5. Limits of Product Level accounting: EPDs

The current EN 16757 framework acknowledges a fundamental constraint: material producers do not know the in-service exposure, surface area configuration, or design life of their concrete in any specific building. EN 16757 addresses this by defining generic "building" and "infrastructure" scenarios and requiring that assumptions be transparent.

While material producers cannot know use conditions in advance, building designers and clients do know (or can specify):

- The location and exposure class of each concrete element (e.g. interior, protected exterior, uncoated facade, below-grade)

- Whether surfaces are painted, plastered, or finished with low-permeability coatings

- The design service life of the building

- The actual dimensions and surface configurations (including articulations, recesses, etc.)

- The anticipated end-of-life scenario (demolition and landfill, selective demolition and reuse, crushing for recycled aggregate, etc.)

This information is not available to the material producer at the time of EPD creation, but it becomes available during design and should inform the building-level carbon assessment.

6. The Case for BIM Integration (The Next)

Building Information Modelling (BIM) offers a solution for integrating manufacturer’s EPD data with designer-specified use condition data. In a BIM model:

- Each concrete element is geometrically defined by the BIM user

- The model can automatically calculate surface areas, volumes, and surface area–to-volume ratios

- Each concrete element can be assigned attributes such as surface finish and design life

- Exposure conditions for spaces and surfaces can be inputted by the BIM user

- The model can determine exposure classes for each surface of each element from element location

- The model can query the project EPD database to retrieve material-specific data for each element and then apply EN 16757 Annex BB formulas with project-specific (use scenario) data

The result is a project-specific recarbonation calculation that follows the EN 16757 methodology while taking into account actual building geometry, exposure conditions and use.

For BIM-level recarbonation modelling to be practicable, digital EPDs for concrete must provide the parameters required by the standards in a machine-readable format. Digital EPDs should also include information on any product-specific recarbonation already claimed so that designers do not double-count or apply conflicting assumptions.

The BIM-integrated tool can then produce a set of outputs for review and reporting:

- Annual CO₂ uptake (kg or tonnes): Average recarbonation per year during the use phase

- Total use-phase recarbonation (B1): Over the design service life

- End-of-life recarbonation (C3 and C4): Separately, allowing the designer to see the impact of recycling assumptions

- Element-level breakdown: Which concrete elements contribute most to recarbonation, helping identify where refinement might improve accuracy

- Sensitivity analysis: e.g. impact of varying design life, changing exposure assumptions, changing surface treatments/coverings or adjusting product selection (whilst ensuring safety and durability is not compromised)

- Whole-life carbon: Total carbon footprint of a project including embodied carbon and recarbonation uptake as well as energy use

This output supports the designer in making informed design decisions based on actual project-specific recarbonation accounting.

Currently, EPD formats do not include dedicated fields for carbonation-specific material parameters. Adding these fields would enable BIM tools to reliably extract the data needed and reduce the need for BIM modellers to manually search EPDs for material specific parameters.

7. Recommendations: Implementing the NOW and Preparing for the NEXT

The uptake of CO2 through natural recarbonation of concrete is significant in terms of absolute quantity and therefore should be recognised and quantified much more widely in concrete carbon assessments. At present, recarbonation is generally not included in North American practice, and some manufacturers choose not to calculate or report recarbonation in their EPDs even where it is technically possible. As immediate actions, GCCA recommends broadening the implementation of recarbonation in EPDs across all regions, including North America, using consistent whole‑life methods. In the medium to long term, the construction sector should progressively shift towards implementing recarbonation calculations at the project level (enabled by BIM), so that whole‑life CO₂ uptake is linked to the actual use, exposure and geometry of each structure.

Recommended Actions:

- North American PCRs: The EN 15804 / EN 16757 framework for product-level recarbonation is well established in Europe but has not been widely adopted in North America and is not included in any standards/PCRs. Relevant standard bodies and PCR committees in North America should extend the assessed lifecycle modules to full cradle to grave and include recarbonation.

- Producer Training and Uptake: Material manufacturers should be encouraged (or required) to declare recarbonation in their EPDs.

- Building LCA Tool Integration: BIM-integrated LCA tools should support input of EN 16757 recarbonation parameters, allowing designers to assess recarbonation at the building level.

- Standardised Material Data Fields in Digital EPDs: Major EPD programme operators should define a standardised set of data fields for concrete recarbonation. These fields should be machine-readable and included in next-generation digital EPD formats.

- Recarbonation calculation by BIM software: BIM software to enable calculation of recarbonation at project level by retrieving relevant data from next-generation digital EPD formats.

9. Conclusion

Recarbonation is the natural process by which CO2 in the atmosphere reacts with the calcium oxide in concrete to form calcium carbonate. Recarbonation is a significant CO₂ uptake mechanism that must be reflected in whole-life carbon accounting for concrete products and buildings. Current EN 15804 and EN 16757 standards establish a calculation method for accounting this uptake at the product level. The GCCA EPD Tool can easily calculate the recarbonation rate according to the standards.

However, the product-level approach has an inherent limitation: material producers cannot know the in-service exposure, surface area, and service life of concrete in a specific building, so they must rely on generic defaults. While these defaults are conservatively chosen to ensure credibility, they may miss variations in real projects.

This paper recommends integration of EPD data from the material producer with designer and client knowledge of building use conditions through BIM-enabled whole-life carbon assessment tools.

Such an approach would make concrete's recarbonation a visible, credible, and design-actionable element of whole-life embodied carbon assessment. It would support the concrete industry's transition to net-zero and enable more accurate comparisons between concrete and alternative materials.

References

Global Cement and Concrete Association. (2025). Recarbonation of concrete in the GCCA EPD Tool. Unpublished technical paper.

DIN/CEN. (2017). EN 16757:2017 – Sustainability of construction works – Environmental product declarations – Product Category Rules for concrete and concrete elements. German and European Standards Committee. https://www.din.de/en

DIN/CEN. (2021). EN 15804:2012+A1+A2 – Sustainability of construction works – Environmental product declarations – Core rules for the product category of construction products. German and European Standards Committee. https://www.din.de/en

Gustafsson, T., & Gustafsson, T. (2018). CO₂ uptake in cement-containing products: Background and calculation models for the IPCC. International Panel on Climate Change. Geneva, Switzerland.

The Concrete Centre. Carbonation of Concrete. Available at:

https://www.concretecentre.com/Performance-Sustainability/Whole-life-carbon/Carbonation-of-concrete.aspx

[1] For unknown exposure conditions the tool considers the most conservative option that minimises recarbonation. For concrete with a strength class below 15 MPa, this is "Indoors in dry climate with cover," while for other strength classes, it is "Exposed to rain."

[2] Source: EN 16757:2017

[3] Source: Gustafsson T, Gustafsson T (2018) CO2 uptake in cement - containing products Background and calculation models for IPCC